Contact Us

Give Us A Call

+90 (242) 241 0305

+90 (543) 496 9535

Send Us Message

Visit Our Location

Bakü Türk Şehitleri Cad. Hüsnü Karakaş Mah. Nihat Bulut Apt. No:14/D Kepez/Antalya

The hidden infrastructure determines a pool’s lifespan and comfort. On our technical systems page, we present our filtration, pump–circulation, heating, dosing, salt electrolysis, lighting and automation solutions—engineered for new builds and renovations with energy efficiency and low operating costs.

What Do Technical Systems Include?

- Filtration & Circulation: Pump selection, sand/cartridge filters, balanced return–suction hydraulics.

- Heating: Heat pumps, heat exchangers, boiler integration and heat recovery.

- Disinfection & Dosing: Automatic dosing, salt electrolysis, UV/ozone support.

- Automation & Monitoring: pH–ORP control, remote access, logging & reporting.

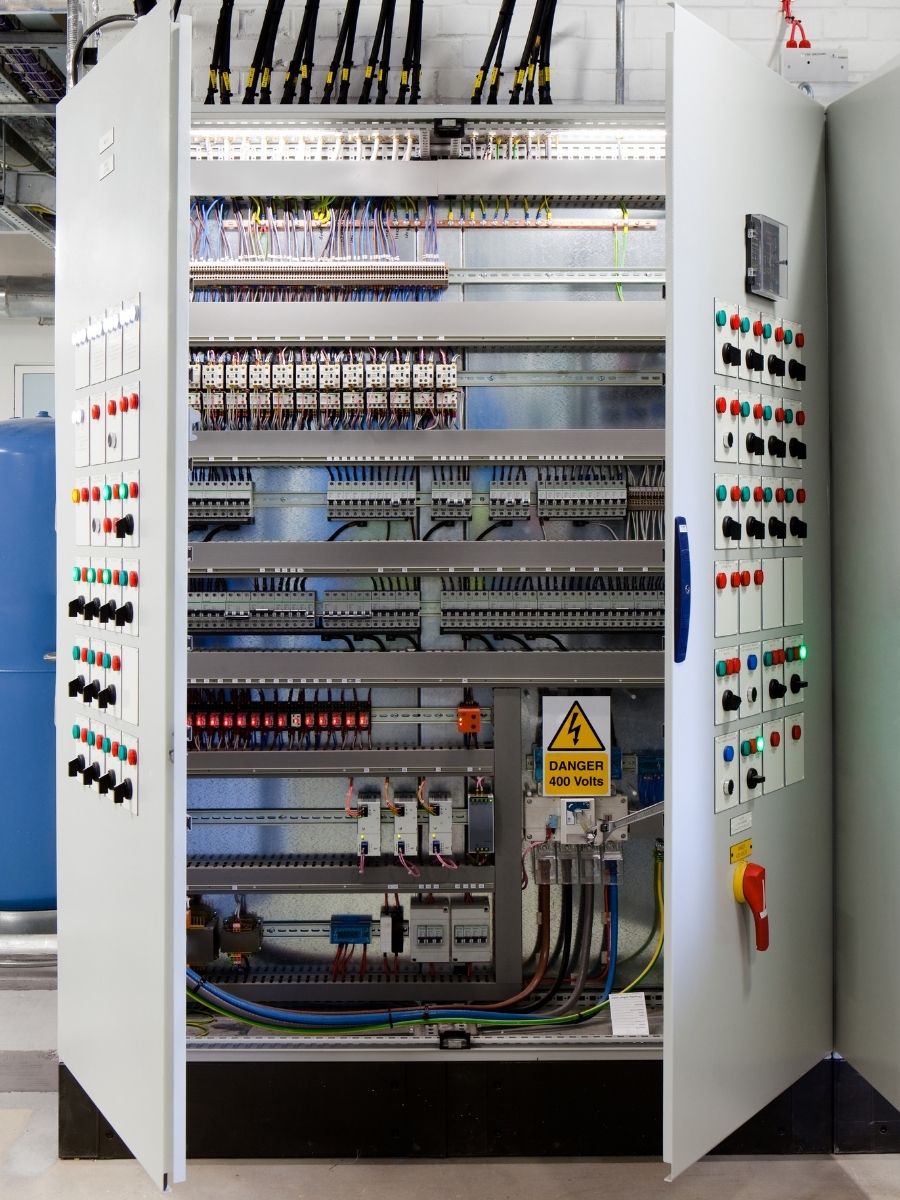

- Lighting & Electrical: IP68 LEDs, drivers, control panels and safety relays.

- Energy Efficiency: Variable-speed pumps, scheduling and insulation strategies.

Filtration & Circulation

Crystal-clear water requires proper filtration and circulation. Flow is calculated from pool volume and target turnover time; the pump–filter pairing follows. Nozzle layout is designed to avoid dead zones and ensure uniform flow.

- Sand filters (multiport valve) or cartridge filters

- Piping and manifold diameters optimized to reduce head loss

- Variable-speed pumps for low consumption and quiet operation

Heating Systems

To extend the season and increase comfort, efficient heating is essential. In Antalya’s climate, heat pumps are the first choice; for rapid heating, integrate a heat exchanger with a boiler/central plant.

- Heat pumps: High-COP inverter models

- Heat exchangers: Stainless/titanium bodies with low primary losses

- Cover and perimeter insulation recommendations to limit heat loss

Disinfection, Dosing & Salt Electrolysis

Stable water quality relies on automatic dosing and measured control. As an alternative, salt electrolysis delivers soft-feeling water with lower consumption; in heavy loads, hybrid UV/ozone enhances performance.

- pH–ORP controlled dosing pumps

- Salt electrolysis (reverse-polarity cells for reduced maintenance)

- Continuous, safe residual control instead of shock dosing

Automation & Remote Monitoring

With a central automation panel, filtration schedules, lighting, heating and chemical dosing are managed from one point. Cloud connectivity logs values and automates alarms and service notifications.

- pH–ORP trends, data logging and reporting

- Remote access with fault alerts

- Optimization scenarios for energy and water consumption

Lighting & Electrical

For visual quality and safety we use IP68 LED lighting. Electrical panels include residual-current and surge protection; cable and component choices comply with pool standards.

- RGB/monochrome IP68 LED projectors

- Panels and protection devices compliant with TS/EN

- Correct beam angles to prevent glare and shadowing

Quick Selection Table

| Need | Recommended Technical System |

|---|---|

| Low energy consumption | Variable-speed pump + larger surface-area filter + heat pump |

| Soft water feel / lower chemicals | Salt electrolysis + automatic dosing + UV assist |

| High bather load | High-flow pump, oversized filtration, precise ORP control |

Design, Installation & Commissioning

- Survey & Analysis: Volume, target turnover time, heating and usage scenarios.

- Design & Calculation: Flow and head-loss calculations, equipment list and piping diagram.

- Installation: Pump–filter, dosing–control, heating, lighting and panel works.

- Testing & Commissioning: Leak tests, instrumentation calibration, user training and handover.

Operations & Maintenance — Sample Plan

| Interval | Checklist |

|---|---|

| Daily | pH–ORP tracking, level/leak checks, surface skimming |

| Weekly | Filter backwash/cartridge clean, pump & fittings inspection |

| Monthly | Dosing calibration, lighting & panel tests, consumables planning |